Choosing the Right Roller Brake Tester for Your Workshop

What is a Roller Brake Tester?

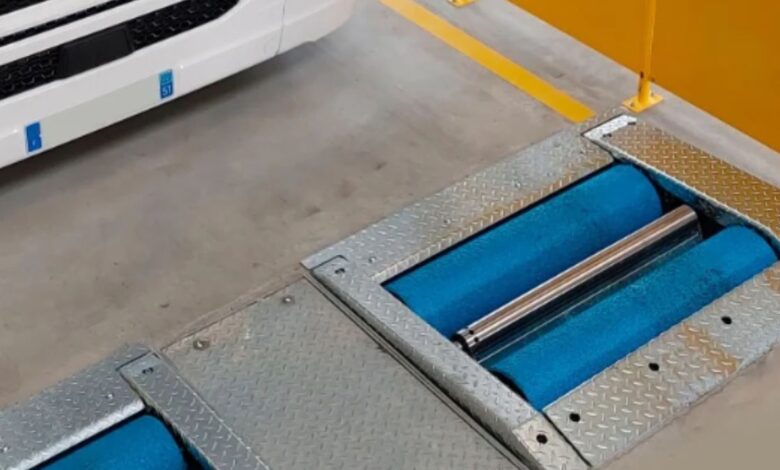

A roller brake tester is a machine used to assess the braking performance of vehicles, particularly heavy-duty and commercial vehicles like trucks and buses. It consists of two sets of rollers that simulate road conditions while the vehicle’s wheels are stationary.

When the vehicle applies its brakes, the tester measures the braking force generated at each wheel. This method provides an accurate representation of how effectively the vehicle’s brakes will perform under real-world conditions.

Why is a Roller Brake Tester Important?

Brakes are one of the most important safety components of any vehicle. Poorly functioning brakes can lead to accidents, especially in commercial vehicles that carry heavy loads.

Regular testing ensures that the braking system is operating correctly and identifies any issues before they lead to more significant problems.

For workshops that deal with a variety of vehicles—ranging from passenger cars to trucks and trailers—a roller brake tester provides several benefits:

- Accurate Testing: Roller brake testers offer precise measurements of braking force, ensuring that the brake performance is thoroughly evaluated.

- Compliance with Regulations: Many countries require commercial vehicles to undergo regular brake tests as part of their roadworthiness inspections. Having a roller brake tester in your workshop allows you to comply with these regulations.

- Enhanced Customer Service: Offering brake testing as part of routine maintenance services can improve customer satisfaction, as clients will appreciate knowing their vehicles meet safety standards.

- Improved Workshop Efficiency: Using a roller brake tester helps mechanics quickly identify braking issues, speeding up repairs and reducing downtime.

Factors to Consider When Choosing a Roller Brake Tester

When it comes to selecting the right roller brake tester for your workshop, several factors must be considered. The following key elements will help you make an informed decision based on your specific needs:

1. Type of Vehicles Being Tested

One of the first things to consider when choosing a roller brake tester is the type of vehicles your workshop services. Roller brake testers come in various sizes and configurations designed for different vehicle categories:

- Passenger Cars: If your workshop primarily deals with light vehicles such as cars and motorcycles, a standard roller brake tester designed for these vehicles will suffice.

- Commercial Vehicles: For workshops that work with heavy-duty vehicles, such as trucks, buses, and trailers, you’ll need a roller brake tester that can handle the increased weight and braking force of these larger vehicles.

- Mixed Use: If your workshop services a wide range of vehicles, from passenger cars to commercial trucks, look for a versatile roller brake tester that can accommodate both light and heavy-duty vehicles.

2. Load Capacity

The load capacity of a roller brake tester is a critical factor, particularly for workshops that deal with commercial vehicles. The tester must be able to handle the weight of the vehicle being tested without compromising accuracy.

Most roller brake testers will specify their load capacity, so ensure that the model you choose is suitable for the heaviest vehicles your workshop services.

3. Accuracy and Sensitivity

The primary function of a roller brake tester is to provide an accurate assessment of a vehicle’s braking performance.

Therefore, choosing a model with high accuracy and sensitivity is essential. Some advanced roller brake testers come with digital readouts and software integration, allowing for real-time data analysis and more precise measurements.

- Frictional Force Sensors: These sensors measure the resistance the rollers encounter when the brakes are applied, offering precise data about braking force.

- Axle Weight Sensors: Many testers are equipped with axle weight sensors, which are necessary for calculating brake efficiency based on the vehicle’s load.

4. Ease of Use and Automation

Modern roller brake testers often come with user-friendly features and automation, making the testing process more efficient and reducing the chance of human error. Look for models that offer:

- Automated Testing Procedures: Some testers can automate the entire brake testing process, from the initial measurement to the final result, reducing manual labor and improving efficiency.

- Intuitive Interfaces: Choose a tester with a straightforward control panel or digital interface to make it easier for mechanics to operate.

- Data Logging and Reporting: Some roller brake testers include the ability to store and print test results, which is useful for record-keeping and compliance with safety regulations.

5. Durability and Maintenance

Investing in a high-quality roller brake tester means that it will likely be a long-term fixture in your workshop. Therefore, durability and ease of maintenance are crucial factors.

Heavy-duty testers with robust construction and corrosion-resistant materials are ideal for workshops that handle a large volume of vehicles.

- Serviceability: Consider how easy it is to service and maintain the roller brake tester. Models with easily accessible parts and clear maintenance guidelines will save you time and money in the long run.

6. Software Integration and Connectivity

As workshops become more digitally advanced, many roller brake testers now come with software that allows mechanics to integrate the testing process with the overall vehicle diagnostic system.

Software that can connect to a workshop’s computer network and store test data digitally is a valuable feature. Some advanced models also offer:

- Wi-Fi Connectivity: Enables easy communication between the roller brake tester and other diagnostic tools.

- Cloud-Based Reporting: Allows for instant access to brake testing data and performance metrics from any device connected to the cloud.

Conclusion

Choosing the right roller brake tester for your workshop is a decision that can greatly impact your efficiency, service quality, and compliance with safety regulations. When selecting a tester, consider the types of vehicles you service, the accuracy and ease of use of the tester, as well as its durability and software features.

By investing in the right roller brake tester, you can enhance your workshop’s operations, ensure customer satisfaction, and provide reliable, safe brake testing services for all types of vehicles.

For more posts, Click here